Welding Cable vs. Battery Cable – Which is Better?

The world of wires is highly vast. Visit your nearest hardware store and you will be surprised with the various types of electrical wires that are manufactured and supplied today. But for the manufacturers and the electricians, the knowledge about cables is highly important. So today in this article we are going to be comparing battery cables and welding cables to see which out of the two is the best option.

What is a welding cable?

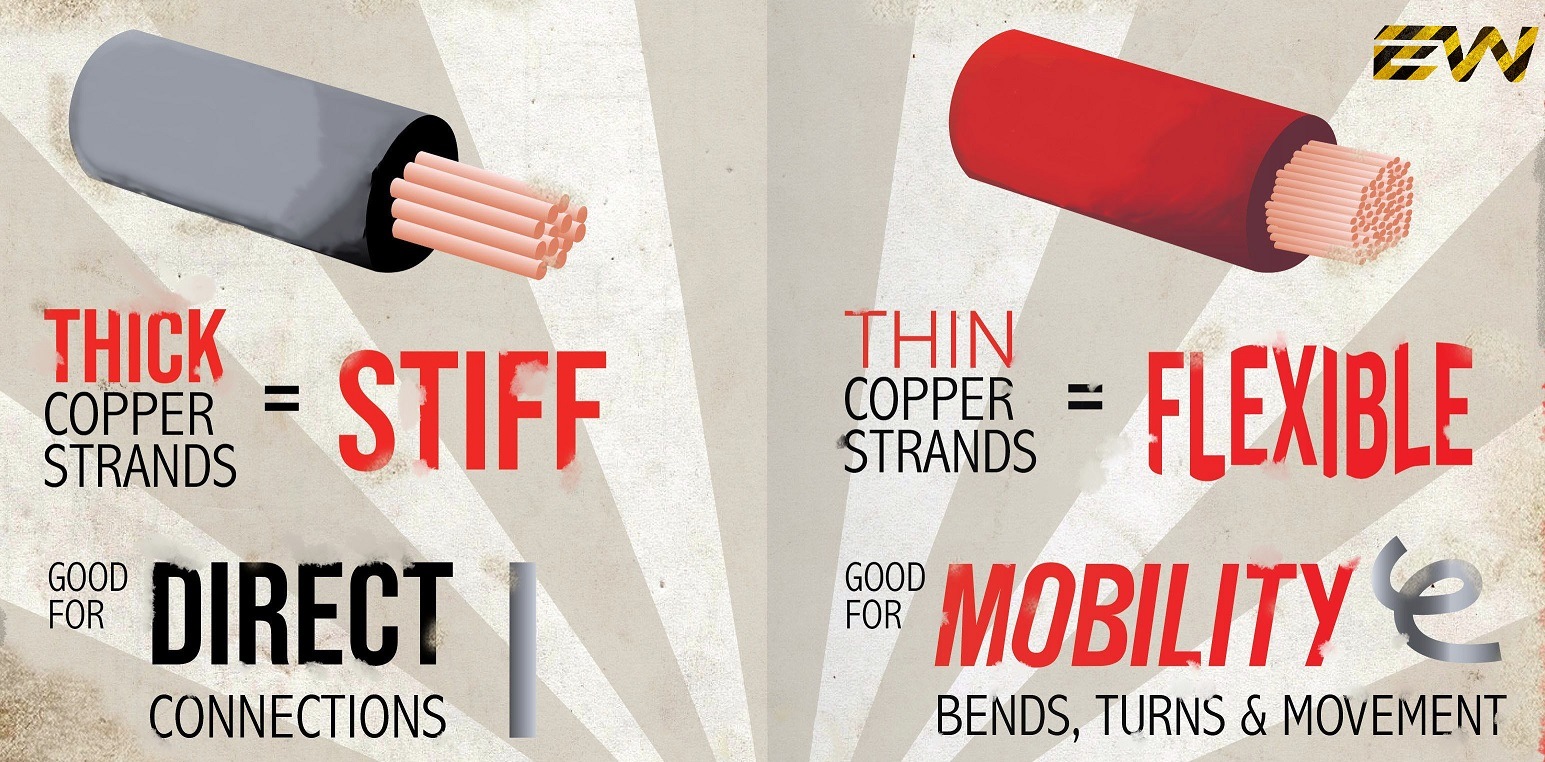

A welding cable is a specialized type of Leading Cable manufacturers which is constructed using a single conductor. The portable cord is mostly made of fine strands of annealed copper conductor which are further covered using a neoprene rubber jacket or EPDM. Its fine construction makes it highly flexible and versatile which is why it is popular among manufacturers in the industry.

Based on the purity of the copper strands used for the construction of the welding cable, the cable has the ability to withstand voltage up to 600 volts and has a temperature rating between -50℃ to 105℃. It is often the best choice for colder climates and acts as a great alternative for battery cable.

Application of Welding Cable

Similar to other cables in the market, welding cable is also used in a number of industries based on its applications. Most commonly, they are used by appliance manufacturers to cater to the voltage needs of demanding applications. This 600 volts resistant cable is also added to the generators and battery as a secondary source of power to handle electrodes. Furthermore, it is also used in the marine industry due to its resistance to water, oil and grease.

What is a battery cable?

A welding cable is a specialized type of leading cable which is constructed using a single copper conductor. As compared to welding cables, the copper strands of battery cable are thicker and are insulated using XLPE or PVC for resistivity feature. Due to its thick strands of copper and loose insulation in the PVC, the cables are less flexible as compared to the other types of cables in the market. There are several types of battery cables;

The cable is manufactured in different sizes ranging from 6 AWG to 4 AWG cable. Since less copper strands are used per conductor thus the cable only has the ability to withstand voltage up to 60 volts. This makes them perfect for everyday usage in small, less demanding and direct appliances.

Application of Battery Cable

Battery cable, similar to welding cable is used in a number of industries for appliance manufacturing purposes. They are mostly used for appliances in which a simple and direction connection is required between the battery and the starter. Due to lack of flexibility, their ideal application is for tools and appliances they come with no curves or folds.

Final Verdict

Although battery cables are simple and easy to use, they are not the best option for high-end, demanding applications. Welding cables are better than battery cables in terms of flexibility, versatility, weather- resistance and voltage handling due to high copper strands per conductor and more resistive insulation. So whether you go with battery cables or welding cables, it depends on your needs.