Thermography for Predictive Maintenance

Introduction

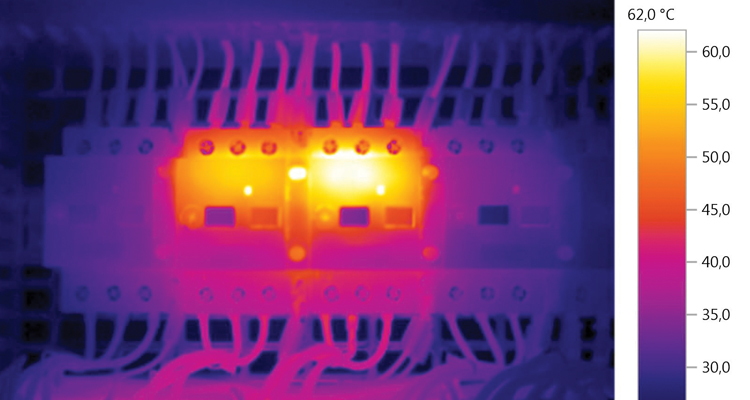

Since heat is often an early symptom of equipment damage or malfunction, it makes sense that it is a key performance parameter monitored in predictive maintenance (PdM) programs. Infrared thermography is a tool that has become more and more widely used for preventative maintenance on mechanical and electrical systems over time. It takes advantage of the infrared radiation properties to extract useful conclusions for the condition of the equipment under test. It is neither non-destructive, nor an interrupting procedure and has no solid substitute

Technicians can use the thermal camera to check the temperature of critical equipment which allow us to track the operating condition over time and quickly identify readings for future comparisons as well.

Thus by monitoring the performance we can schedule maintenance only when it’s required which will result in unplanned downtime due to equipment failure and can also contribute to extend the working life of machine assets.

“It helps to identify problems early, document them immediately, and correct them quickly. The longer system faults are ignored, the more serious and costly they are to repair.”

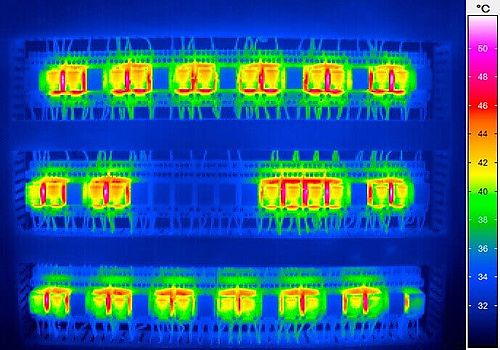

Examples of application of Thermography

Thermal camera advantage over Temperature Gun

Return on Investment

A proper predictive maintenance program can provide a savings of up to 30-40% over reactance maintenance according to studies by Federal Energy Management Program. Also according to some other independent surveys regarding industrial predictive maintenance the following was knows:

IR thermal imager

Simple, fast and effective

$

398.99

Fluke VT04

Easy to use !

$

559.99

FLIR C2

Compact Thermal Imaging Camera

$

495.09