Motor Single Phasing: Causes, Analysis and Prevention

Single phasing or also known as phase failure can be a huge problem especially in a manufacturing plant where having a downtime of any machine can result in a huge production loss. But sometime single phasing can be can happen naturally – from the incoming grid when one of phases of the utility supplier fails.

In this article we shall learn what is single phasing and how we can prevent it.

What is Single Phasing of Motors?

Single Phasing of a motor is a scenario when one of the phases of the motor fails resulting in the operation of the remaining two phases and is possibly the worst case scenario of a voltage unbalance. If a three phase motor is running when the phase failure occurs, the motor will try it’s best to deliver the full horsepower, enough to drive the load until the motor burns out due excessive current being drawn. Let’s go in more details and try to find out why single phasing can occur.

Causes of Phase Failure

There could be numerous reasons which can cause single phasing. Some of them are listed below:

- When the incoming supply from the grid loses one of its phases maybe by wind, storm, lighting etc. and there is no protection device in the main distribution panel.

- Damaged switch or circuit breaker on the main, feeder or motor branch circuit.

- Open Winding in Motor

- ANY open circuit in ANY phase which could happen ANYWHERE between the secondary of the transformer and the running motor.

What Happens During Single Phasing?

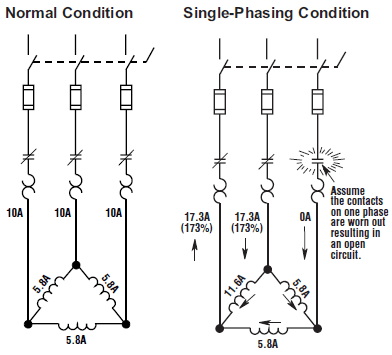

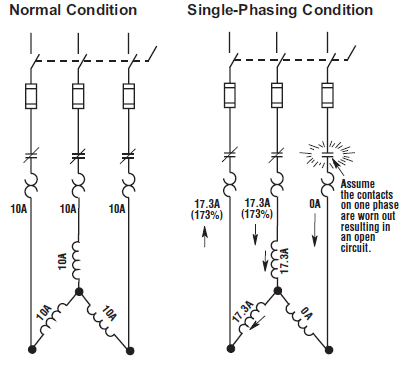

During phase failure the current in the other two phases theoretically increases by 173% or by a factor of 1.73 of the normal running current which can go all the way up to 200% because of the power factor changes. This results in current being drawn above the safe limit which can heat the coils inside the motor leading to motor failure.

It is interesting to note, during phase failure the motor temperature may increase at a rate greater than the increase in current also the speed of the motor will reduce and rpm will fluctuate resulting in noise and vibration, which is really dangerous and lead to motor being burnt out very quickly if there are not protection device available to cut off the supply. Moreover if the motor is in the sopped condition it won’t start during phase failure.

How to Protect Motor from Phase Failure?

Motors are some of the most valuable assets which the maintenance department of any organization needs to take care of. They are the backbone of a manufacturing factory and therefore very critical. Thus it’s very important to prevent any unplanned downtime because of phase failure of the motors which will not only lead to downtime but also loss in financial terms.

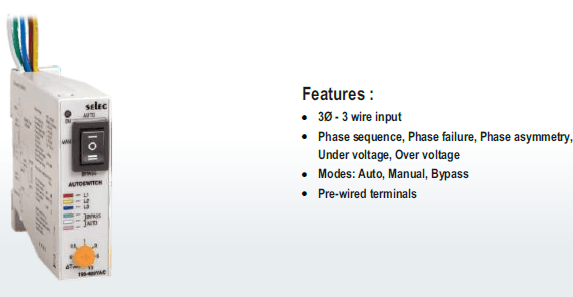

Using a single phase preventer is indeed one of the most common ways of protecting the motors against phase failure. The single phase preventer works like a negative sequence relay and provides protection up to the motor terminals. The basic operating principle is by deducting the negative sequence components of the system.