How are Bottles Printed With a Screen Printing Machine?

So you have a bottle of wine, or beer, or just an empty bottle that you want to reuse. You may not want to bother with trying to write on it with a pen or marker, so what are your options?

Since the printing process is different for each type of material being printed, there are actually several ways through that bottles can be decorated. The most common way that bottles are printed is by using a screen printing machine which you can buy online from different website like once-tech.com

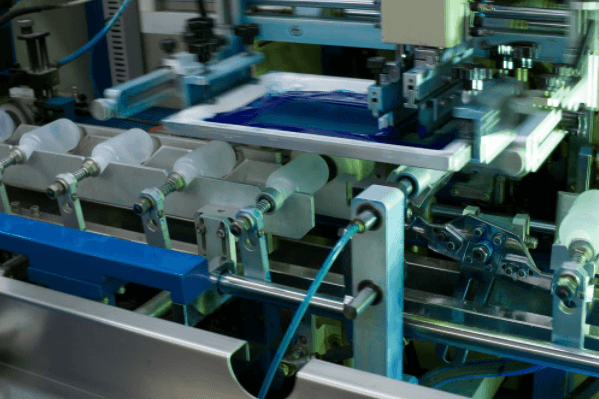

Screen Printing Machine

Screen printing is a popular printing method because it is an affordable way to produce large quantities of objects. It can also be used to print a wide variety of objects, including textiles, paper products, and plastic objects. Screen printing is often used for printing logos and designs on products.

If you are looking for a screen printing machine, there are often websites available that will allow you to purchase one. These machines can be expensive and may require a high initial investment. It is important to research the different types of screen printing machines that are available before purchasing one.

Silk Screen Printing

Screen printing is a process that uses mesh fabric to transfer ink onto a bottle. The artists cover the surface of the bottle with a thick layer of emulsion and place it on an aluminum frame. They then use a squeegee to pull ink across the frame's mesh fabric, leaving an outline of ink on the inside of the frame. The squeegee also removes any remaining emulsion. While this method is effective, there are several disadvantages. The thick layer of emulsion makes it difficult to remove the bottle from the frame without damaging either part, which can cause problems if there are errors during printing. The ink needs time to dry before the squeegee passes over it again. If artists try to print too many bottles at once, they must wait until the batch dries completely before adding another layer of paint to the screen and printing more bottles. This increases production costs because artists need enough frames for everyone on staff to print an equal number of bottles simultaneously or be forced to stop work while others dry. Using a silk screen simplifies the process by eliminating many steps required in traditional screen printing. There is no need for a thick layer of emulsion, so artists can easily remove the bottle from the frame. The silk screen also allows for more accurate printing because it's less likely to cause smudges or distortions in the image. Finally, the ink dries quickly, so artists can print multiple bottles at once without having to wait for each one to dry.

Silk Screen Printing Is Expensive

While a silk screen is more expensive than traditional screen printing mesh, the benefits often outweigh the costs. Screen printers can produce more bottles in less time while maintaining high-quality standards. This makes silk screening an attractive option for small businesses and individuals who want to create custom bottles on a budget.

Type Of Ink

The type of ink that is used will depend on the type of object that is being printed. For example, if a bottle is being printed, then a water-based ink would be used. This type of ink is non-toxic and environmentally friendly. It is also easy to clean up if any spills occur.

Conclusion

Screen printing is a very old process that has been used for centuries with the help of bottle printing machine. Printing bottles with a screen printing machine is an intricate process that requires precision and patience. We hope this article has given you some insight into the meticulous work required to create your favorite bottled beverage.