Top 5 Panel Enclosure Design Essentials

It would be challenging at times to create an optimal enclosure design that perfectly resembles the user’s requirements. A basic panel enclosure includes simple yet efficient operator controls, user-friendly functions, easy to maintain, cost-effective along with an attractive appearance.

Thus, engineers need to consider a few things before designing a perfect enclosure. This will save money, effort and give you an impeccable panel enclosure.

Control panel design is not just about the dimensions of the cabinet or worrying about the rating of IP protection. Instead, it is about creating a design that is simple yet competent.

Now it is time to recreate an enclosure that can fight application environmental odds which can be done by infusing innovative designs and trendy manufacturing techniques to design an ‘ideal’ panel enclosure.

Control Panel Enclosure Design 101

It is not difficult to create one if you follow a proper planning strategy, no matter how complex it is. This blog will help you with some key things to remember while designing so that you save time, money and endless efforts of unnecessary redesigning. Scroll down to know more.

Start by preparing physical layout drawings

Producing schematic drawings is a total waste if you don’t take the pain of preparing physical layout drawing. Always remember, a good control panel design caters to physical and electrical requirements to understand all potential problems.

Prepare a physical layout of your control panel. It will help you to design an accurate enclosure and think about upcoming problems and delivery delays, which will be known during production and testing.

Make sure you strictly adhere to the standards laid by the International Electrotechnical Commission (IEC). These are the international standards that examine if the control panel is safe for use and satisfy market requirements.

IEC 60204-1: It applies to electrical equipment that works with higher nominal supply voltages and should not exceed 1000V for alternating current (AC) and not exceed 1500V for direct current (DC) and a normal supply not more than 200 Hz.

IEC 61439-1&2: It includes general rules for low voltage switchgear and control gear assemblies. These standards help in proper designing of control panels.

Choose a reputed enclosure manufacturer that follows related guidelines!

Selecting the best metal

While designing a panel enclosure, you need to choose a strong metal, its thickness and other features to prepare a long-lasting and durable panel enclosure. There are various metals like stainless steel, aluminium, carbon steel, copper, etc. having varied characteristics.

Stainless steel: It is a popular choice owing to its strength and ease of fabrication. This type of steel is highly corrosion resistant due to the presence of chromium and nickel. To get that aesthetic appearance, it can be powder coated or left unpainted.

Pros

- bacterial and fungal resistant

- easy to clean

- chemical and water-resistant

- capable to withstand extreme pressure

Cons

- difficult to modify

- not scratch resistant

Aluminium: Panels made from aluminium are lightweight and corrosion-resistant. It can also be anodized that puts a hard, durable and protective oxide coating. Aluminium is used widely to prepare sheet metal enclosures and parts.

Pros:

- non-magnetic

- obtained in a wide range of sizes

- quality finish

Cons:

- provides sharp edges when modified

- thermally conductive

Carbon Steel (Hot/cold rolled): This low carbon steel comprises of a hot or cold finished steel produced by passing bar stock between a set of rolls.

They are affordable and must be galvanized or painted to resist corrosion. Carbon steel is considered to be the strongest material that is impact resistant while maintaining aesthetics.

Pros:

- chemical, moisture and water-resistant

- easily painted or powder coated

- easy to clean

Cons:

- not scratch resistant

- difficult to modify

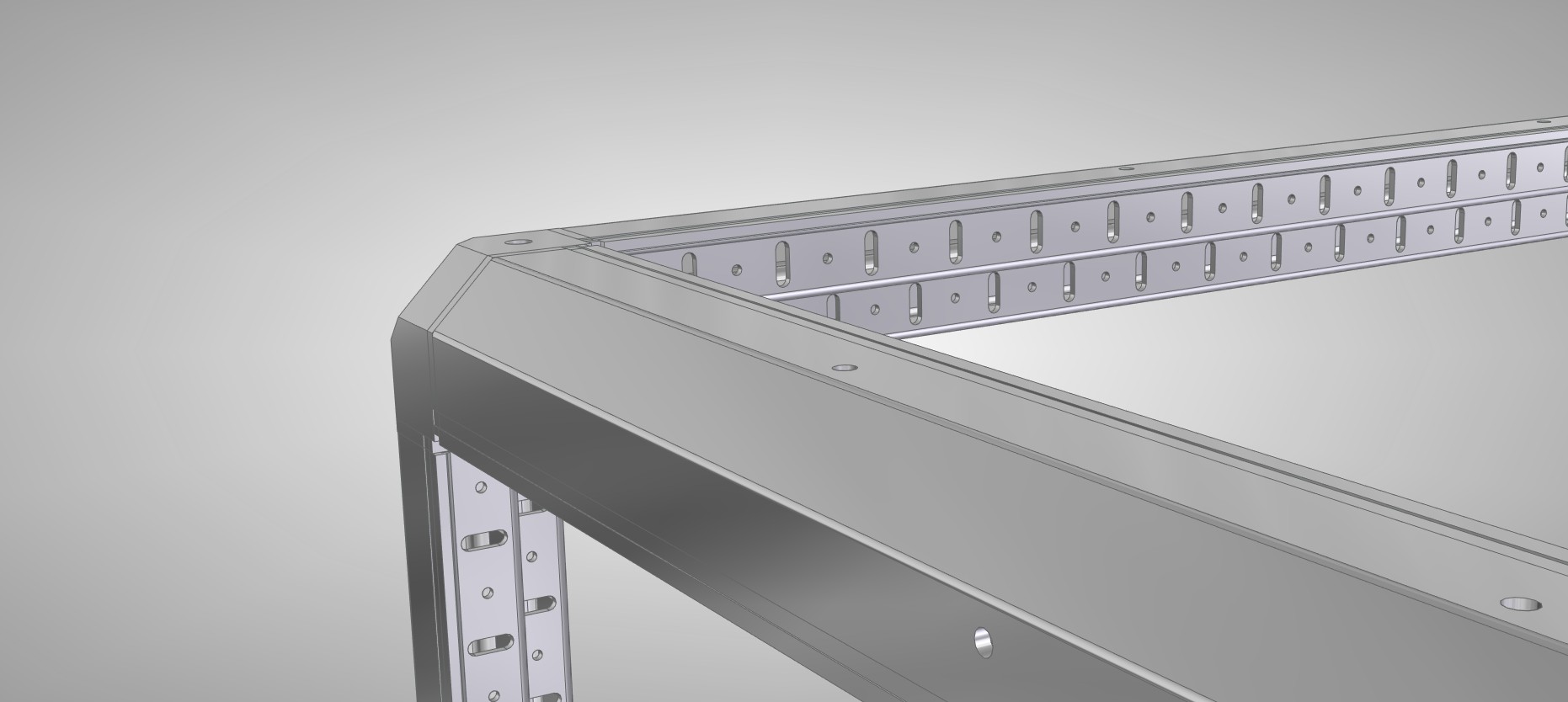

Understanding the concept of bending metal and bend radius

As known to everyone, sheet metal enclosures and other metal parts are bent using a press brake or folder. While bending, the metal the corners tend to have a radius since it cannot be bend into 900 edges.

The role of the designer is to control this by specifying a bend radius (the radius of the inner surface of the bend obtained by adding the inner radius and the metal radius).

Thus, it is important to select a proper bend radius that suits your needs. Also, consider the intersection of two bend lines and make sure you remove the extra material to prevent bends from interfering with each other.

Cutouts should be placed at a standardised distance from the bend radii as it can increase the risk of flaring or cutout stretching.

Climate control accessories

It is important to efficiently manage both heating and cooling loads within the enclosure to maintain reduced energy consumption. There are several climate control options for panel enclosures like:

- Enclosure heaters

- Fans and heat exchangers

- Thermoelectric coolers, etc.

Ensure thermal management by adding accessories like thermostats, filter, water distribution, air routing, hygrostats, etc.

Design one based on the environment where they will be placed

It is essential to consider the location and the surroundings wherein the enclosure will be placed. Different enclosures have different needs considering their location the surroundings, which can cause harm to your equipment.

While indoor enclosures can lead to overheating and cause system failures and premature equipment breakdown. For say, an electrical enclosure placed inside an industry can come into contact with the chemicals, surrounding materials, corrosive metals, harsh climate, etc. Thus, it won’t be wise enough to place it near furnaces or other heating substances that can also heat your electrical components.

Also, outdoor enclosures are affected by dust, dirt, strong winds, rain, snow and other climatic conditions that may hamper your enclosure operations. Taking all these factors into account, create one that helps to withstand these problems.

Author Bio: Hi, my name is Dennis Benson and I have a keen interest in blogging regarding engineering and industrial topics.