What is Investment Casting Process And its Applications?

Investment Casting Process

The investment casting process involves some developmental process for manufacturing features of products such as cost, viability to produce. Further, those things convert “Molten Metal” into a single operation process. The shape of the product doesn't matter, it can be used to make any type of figure.

How Investment Casting Process Work?

The investment casting process involves different engineered components with maximum wastage of materials and machinery. Besides everything investment casting process is one of the largest depths in the world.

What Is Investment Casting?

Investment casting provides great freedom and independence to do work. Work can be incorporated into investment casting manufacturers.

Now important thing is to understand what is meant by investment casting and how it can be used in the investment casting process?

What Is Investment Casting Procedure?

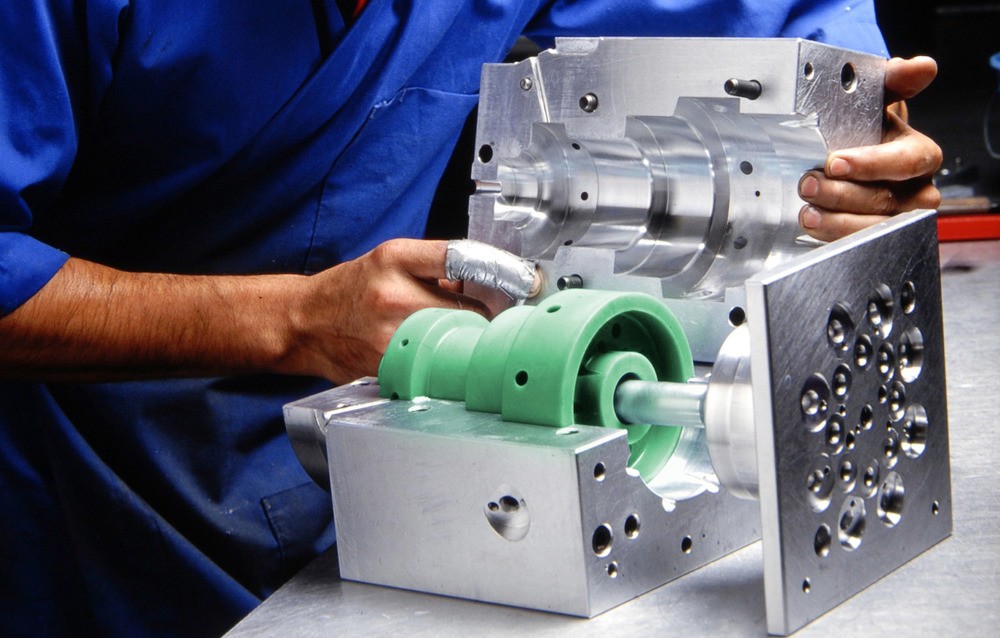

This term investment casting is a casting of employs made up of ceramic shell which is cast around a wax pattern.

Investment Casting Companies

Different investment casting companies are providing three casting production lines. All over the world, high-quality castings have been produced by foundry Dawang casting widely. Investment casting adopts automatic moldings and a pouring system.

Industries have committed to giving high-quality precision investment castings. Designs are manufactured in different house casting. Investment casting manufacturers are additive to manufacture through different procedures.

Dawang casting foundry is the most popular steel investment casting manufacturers. Their services include metal casting and stainless steel casting. Products of Dawang casting have been spam into different industries. They are not limited to specific industries.

How Much Beneficial Are Investment Casting Companies?

Precision investment casting

Another name of investment casting process is precision investment casting. It is a procedure of manufacturing wax patterns with dissimilar forms. Refractory ceramic material is used to make these manufactures.

Advantages of Investment Castings

If permanent tooling is used that will be more than expensive for low-quality products. Initial costs help a lot to cast companies in evaluating either the investment of casting will bring great value to the company. To produce the complex parts the investment cast tools have consisted of multiple parts. Read more

What Are Investment Casting Features?

Range of Sizes Investment Casting Companies

Investment can be cast in different sizes and they do have limited size ranges. It is also possible to produce cast investments through the size range of investment molding. The molding process has excellent results, investment casting manufacturers most of the time is selected over the molding process

It has shown the finest and excellently finishes surface. Dawang steel casting products are high in quality and used for good maintenance of investment casting. A wide range of property is structured through casting materials. Because this can make an absolute object according to demand.

Slight Small Structure Ranges

Through metal, injection die patterns are typically made of an investment casting process wax. Investment molding is a procedure where a wax pattern is made into the exact shape of which item to be cast. One of advantage of investment casting is enclosed applications are the best choice for investment molding.

Very small shapes can be problematic because that use cores and they can be challenging.

What Is Investment Casting And How Does It Work?

Investment casting wax manufactures an intense type of product which are precise components. The wax is surrounded by a ceramic shell that is covered with the wax. Then the wax is converted into the next procedure in which wax is melted and transferred in a boiler.

Investment casting applications term investment casting is derived from the method of process in which different applications and patterns are selected. It layering the right layer of wax into a molding die was a pattern most of the time die because of the complexity of solutions for many different kinds of objects. The cost of any shape which is bigger in shape and it has a larger dimension can cause castings preciseness in the product.

In investment casting applications products can provide different net shapes with a significant cost in investment casting products

Investment casting products are complex, due to several aspects of their complexity and global desires it is a relatively luxurious procedure. Though its benefits are more than its cost and it is a lifetime expense. Investment casting products usually take 7 days to get into exact investment casting wax and then they pursue their work. Most of the time is taken for drying the ceramic. It takes parts for superior dimensional accuracy.

Featuring integrity is an important feature to process the work of investment casting wax.