Machines that save your cement plants from being shut down due to dust pollution

Do you know what resulted in the invention of dust collectors? The answer is the cement plant. No matter which production link in the cement plant, high amounts of dust are generated and discharged with the exhaust gas. The dust not only seriously pollutes the air but also affects the health of the cement plant employees and surrounding residents, so dust collectors came into being.

The earliest dust collector was just a rectangular sedimentation tank, which could only settle large particles, the dust collection efficiency was pretty low, so it was gradually eliminated. But up to now, it may still exist in shaft kiln cement plants in some backward countries or remote areas.

With the promotion of environmental protection legislation and the rapid development of cement industry technology, the dust collectors of cement plants are constantly updated. Cyclone dust collectors, electrostatic dust collectors, and bag dust collectors have been invented successively. The capacity to treat waste gas has increased from thousands of cubic meters per hour to millions of cubic meters per hour.

At present, in the modern large-scale dry process cement plants, small or medium bag type dust collectors are predominantly used for treating waste gas produced in cement raw material crushers and feeders, electrostatic precipitators are for dust produced in cement raw material mills and cement mills, and large bag filter or electrostatic dust collector is used waste gas produced by cement kiln, clinker cooler, coal mill, and cement dryer.

Dust collectors in the modern large-scale dry process cement plants

Production Links | Types of Dust Collector | Emission Concentration |

|---|---|---|

Raw material crushing and feeding | Bag filter | ≤100 |

Raw material grinding Clinker calcination Raw material drying Coal grinding Cement grinding | Bag filter or electrostatic precipitators | |

Cement bagging system Cement bulk loading system | Bag filter Bag filter |

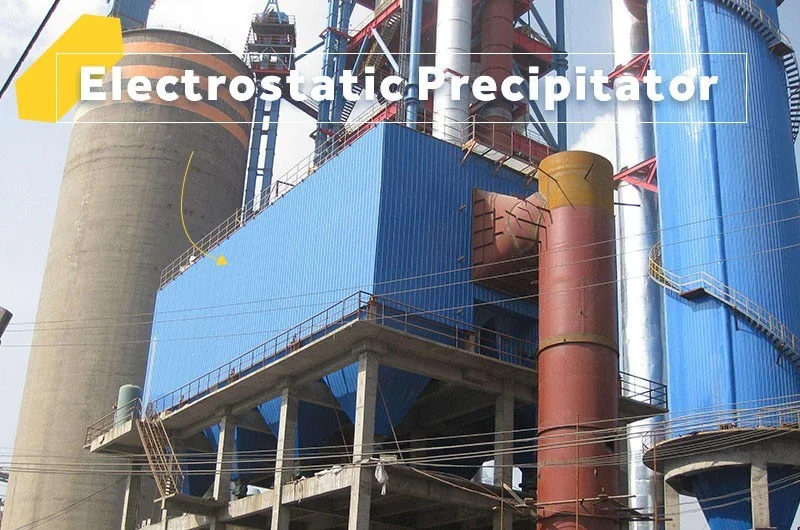

Electrostatic Precipitator

The electrostatic precipitator is a dust collector that uses electrostatic force to separate dust from the flue gas. Its working principle is shown in the following video:

Cement plants have adopted electrostatic precipitators for decades and witnessed the development of electrostatic precipitators. From single tube to multi-tube, from single-chamber to multi-chamber, their volume and waste gas treatment capacity is getting bigger and bigger. Therefore, most large cement plants tend to use electrostatic precipitators in high-temperature processes. When the dust specific resistance of the dust meets the electric field requirements, the dust collection effect is ideal, and the emission concentration can reach 150-50 mg/Nm3.

Bag filter

The bag filter is a dry-type dust filtering device that uses filter materials to capture dust. Its working principle is shown in the following video:

Working principle of the bag filter

The development of bag filters is basically the development of filter material. The revolutionary technology of filter material is the PTFE coating technology first developed by DuPont company of the United States. The revolutionary significance of PTFE coating technology is that it can prevent dust from passing through the polytetrafluoroethylene film and get rid of surface dust timely.

Efficient dust removal equipment is essential environmental protection equipment for cement plants to achieve green production. They are also the predominated pollution control equipment for large factories such as thermal power plants and smelters.