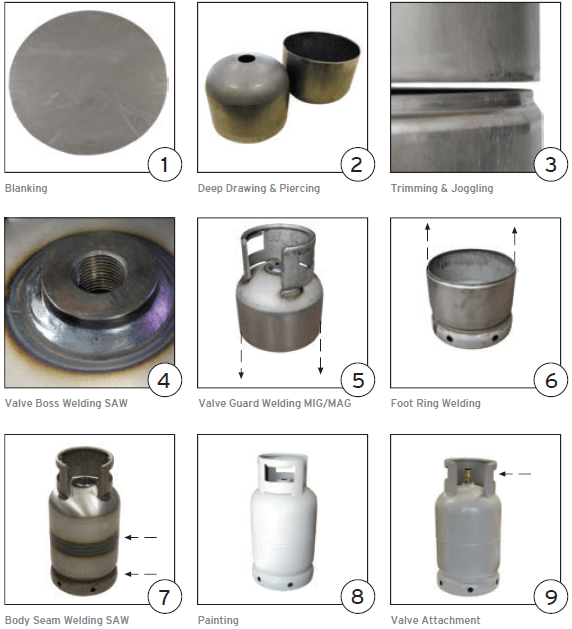

Cooking Cylinders Complete Manufacturing Process

If you are wondering how cooking cylinders which we use at home are made you have to the right source to learn. In this post we have a dedicated video as well as a detailed article explaining the step by step process.

So let’s begin!

Key Manufacturing Processes

Cooking cylinder production is done within the guidelines of the international standards such as EN 1442. It involves several process as listed below:

Cooking Cylinder Production is composed of several sheet metal forming, surface treatment and testing processes. The process starts with blanking, deep drawing and piercing, trimming and joggling. Next are the welding operations for valve boss, valve guard ring, foot ring and the two halves. The finished cylinder is then heat treated, tested, shot blasted, painted and then the valve is attached and final tested.

We shall now look into each process in more details.

BLANKING AND BODY FORMING

In the core of the forming line there stands a versatile double action hydraulic deep drawing press that forms the cylinder halves out of round blanks that are blanked by a double blanking press. The edges of the upper and lower halves are further processed by trimming and joggling machines to the perfection stemming from the sheet metal forming expertise to make them ready for the body seam welding, with or without degreasing.

FOOT RING (BASE RING) AND VALVE GUARD RING (COLLAR) PRODUCTION

Starting either from coiled strip material or already cut sheet steel plate strips, the different shapes of foot rings and valve guard rings require different process steps, different forming machines and different die sets all designed and manufactured in implacable adequacy. The typical process steps involves logo embossing and production data marking under single action hydraulic presses, serial number marking by hydro-pneumatic marking units, blanking of foot ring and valve guard ring blanks, round bending of the blanks, MIG/MAG welding of the foot ring blanks and forming of the final shapes using precisely engineered forming die sets under forming presses to ensure the welding quality in the welding line.

VALVE BOSS (VALVE NECK OR NECK RING) PRODUCTION LINE

The steel rods of the neck ring start off material are first cut in required dimensions and precision by saw, the pieces are induction heated up to forging temperature of 1200 °C, de-scaled by de-scaling hammers and forged under the forging press in the die sets to get the performs to be further processed by flash trimming and hole piercing operation followed by the precise turning operation to get the final shape with valve threads.

WELDING, HEAT TREATMENT & HYDROSTATIC TESTING LINE

The submerged arc welding technique is applied on the welding of body halves on the seam welding machine and generally on the welding of the valve boss to the upper cylinder half. The welding automats with reliable welding power packs and control units are utilized to achieve the uncompromising weld quality with degree of automation needed for the required production capacity per customer. The MIG/MAG welding technique is applied for the welding of foot rings and valve guard rings with the body halves. In order to relieve all the stresses caused by forming and welding operations, the cylinders are passed through a heat treatment furnace where they are heated up to 930º C degrees of temperature for certain time before getting cooled gradually.

The hydrostatic testing of the heat treated Cooking Cylinders can be done on automated carousel type machines or on fixed station type machines to increase the internal pressure up to 35 bars for visual inspection as per requirements of the cylinder design specifications.

SURFACE COATING & FINISHING LINE

The Cooking Cylinder surfaces are shot blasted by the shot blasting machine in order to clean up the scales caused by the heat treatment operation to prepare the surface for the painting and / or zinc spraying. The double layer oven cured painting of the cylinders is achieved automatically by the robotic paint application system in the painting line as the cylinders are conveyed on an overhead conveyor system through the primary and final coat painting cabinets separated by flash off tunnels before they get cured in the canopy type modern paint curing oven. After the tare weighing and marking of the cylinders, the valves are attached by automatic torque controlled screwing machines and tested against any leakage at the valve region by the pneumatic leakage testing machine of the finishing line. One of the batch type quality control equipment called by the international standards are the burst expansion testing unit where the volumetric expansion ratio and the burst pressure is measured to the full satisfaction of even most stringent requirements.

COOKING CYLINDER VALVE PRODUCTION

The valves of Cooking Cylinders are made out of brass material by forging. The induction heater, the forging press, the flash trimming press, the shot blasting machine, transfer machines to manufacture valve body pieces, the CNC lathes for smaller valve pieces, the washing machine, the tooling and die sets are the general manufacturing line machines that are engineered for the specifically designed valves from the customer. The valve pieces are assembled on the assembly and testing line where operational turn on turns off pressure levels and safety release pressure levels are adjusted, set and tested as per applicable international standards.

For more information visit : https://www.repkon.com.tr/en