What Are Cone Crushers? (All You Need To Know)

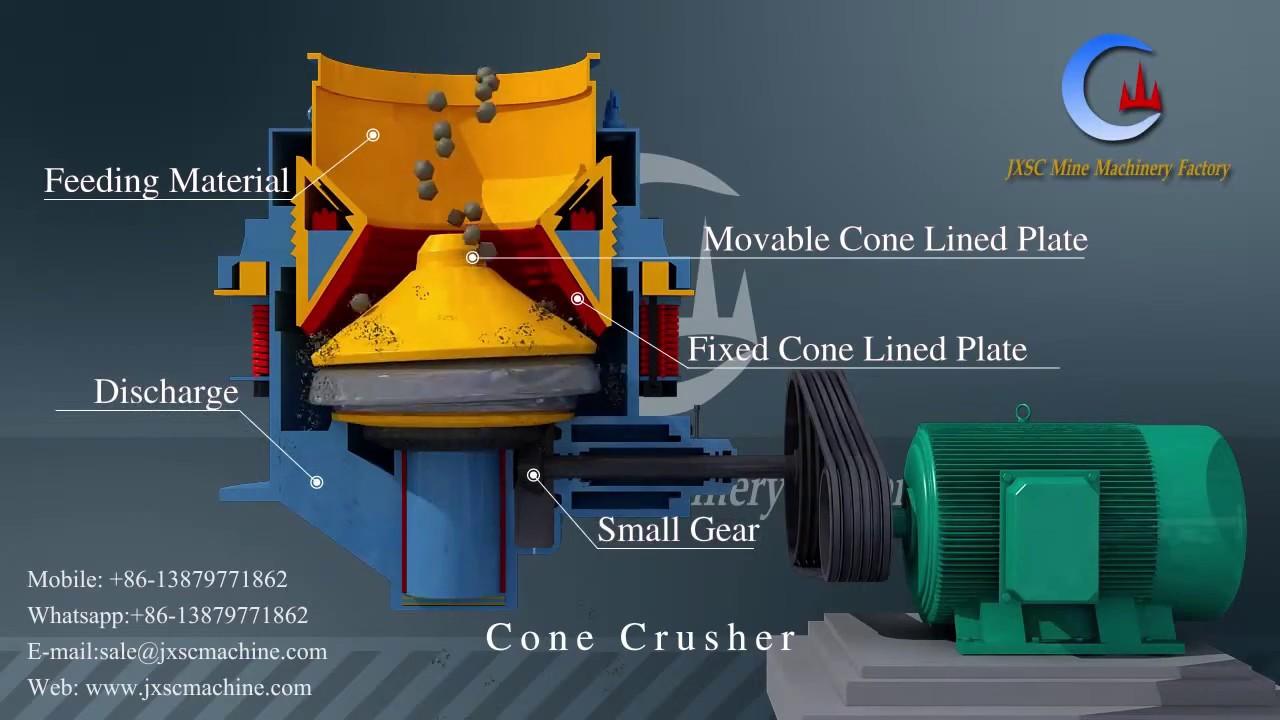

Cone crusher is a type of machine widely used in urban construction, which basically reduces the size of the material with the help of compression, squeezing or breaking down between stationery and moving piece of steel. The size of the output material is controlled by managing the gap between the moving and the stationery steel parts at the lowest point. As the wedge inside the Cone Crusher rotates this cause the compression within the chamber resulting in the material to break down into smaller pieces as it goes down the wear liner. The crushed material then discharges from the bottom of the machine.

In simple words cone crushers are designed to reduce the size of the raw material or feed.

Advantages of Cone Crushers

Cone Crusher is powerful equipment which comes with lots of benefits and can be really helpful for mining industries where it can practically be used. Following are some of the advantages:

- The low time consumption leads to increased and efficient productivity.

- The whole automated and optimized system requires least manpower usage which would have not been possible through other manual ways of crushing.

- Though Cone Crushers might looks complicated on the surface however they are easy to maintain. There are not many moving parts and they damage less often but obviously a good regular maintenance schedule should be in place.

- The operating cost of the cone crushers is low and therefore makes it economically viable. With the improvement in manufacturing technology manufacturers are making them more efficient and cost effective to run. Most of the cone crushers nowadays are computer controlled and are carefully optimized to get the most from them.

- The raw material fed into the crusher discharges automatically once crushed. This becomes possible only through its remote intelligence, which is operated by a remote.

- Cone crushers are used for all types of crushing needs even for waste recycling and demolition solutions.

Disadvantages of Cone Crushers

With advantages there come some disadvantages also and cone crushers are no exception. Here are some of the disadvantages:

- Cone crushers are best when it comes to perform with hard materials but the machine is not meant for soft or viscous materials like clay. They are ideal only for hard materials since viscous material can damage or jam the machine.

- Cone crushers do not provide uniformity in final product. Although they are best for wide range of materials but few materials demand uniformity which is not possible through cone crushers.

- The biggest problem faced with cone crusher is the size of the raw material as the crushers are restricted to certain amount of size. The raw material needs to be pre-dimensioned as per the capacity of the crusher, if the size of the raw material is larger than the capacity of the crusher then in this case the raw material will need a first stage of crushing prior they are fed into a crusher. This ultimately becomes more time consuming.

- The cone crushers are considered for the secondary or the third stage of crushing for their constrain of feed limitation.

How Does It Work?

Like any other crushing machine this crusher also starts with the feed opening or the main shaft at the top of the crusher for the raw material to be fed. The raw material is dropped into the opening which goes inside crushing chamber.

Then comes the mantle, which is made up of steel and iron. The mantle rotates or gyrates but not in a perfect circle rather in different motions in order to crush the material properly. Mantle swings crushing the stones against the concave, breaking them down into smaller particles. This is called as interparticle crushing.

The feed is crushed and drops or falls down through the opening at the bottom of the crusher.

Industries Where They Are Used

Cone crushers are used within these industries in order to refine or break down the raw materials:

- Mining Industries

- Concrete Industries

- Coal Mines

- Aggregate

- Quartz Sand Mining

- Construction Industries

- Recycling Industries

- Mineral Mining and Processing Industries