Benefits Of Using CNC Machining For Rapid Prototyping

Today manufacturers choose CNC Machining because it has taken the place of traditional engineers. Earlier engineers took manual control of routers, shaping machines, center lathes, vertical millers, etc. But now CNC machines have overcome the crowd through their versatility and efficient functionality. Absolutely it is cog in the machine!

They're built in computerized commanded programs rather than manual tasks and that is the reason one machinists can run multiple machines meanwhile.

As for the concern of CNC Machining in the Rapid Prototyping industry, it offers you much leverage to produce fast prototypes in computerized equipment, engineering models, and quality end-use parts within no time.

Rapid Prototyping includes specific manufacturing techniques to make or prepare high-quality physical parts of 3D design concepts.

As the name suggests rapid means quickly and Prototyping defines mock-up, so quick physical mock-up of your products within the least possible time.

The prototype is used to improve the design along with a number of leverages without investment in hard tooling. But the invention of CNC Machining and 3D printing has changed the definition of rapid Prototyping.

Before diving into the benefits, let's make out what CNC Prototyping is and how it works first.

What Is CNC Prototyping

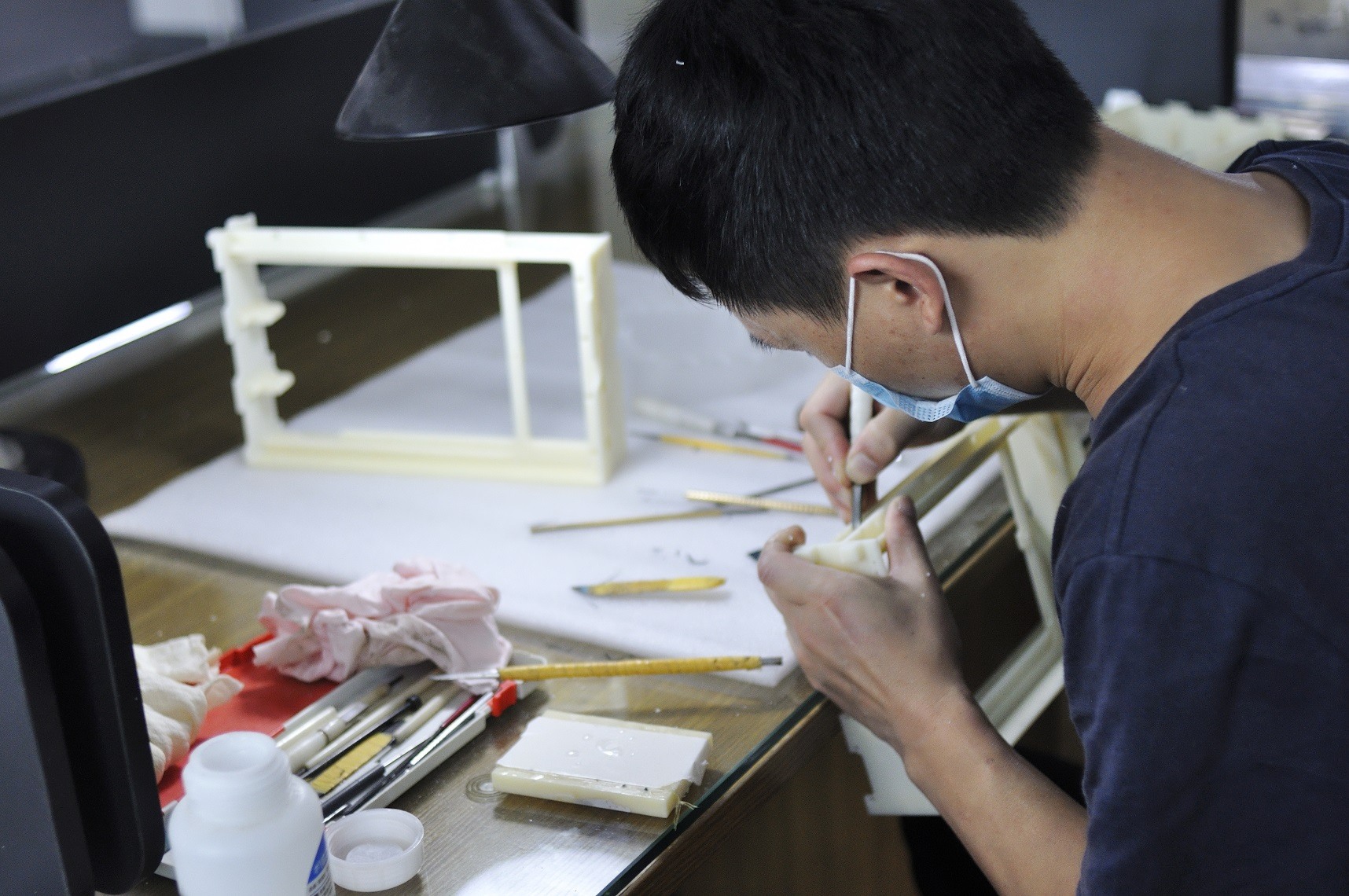

CNC Prototyping uses 3D CAD design as the input and fabricates the part through milling or computer control cutting. It helps you to prepare a model first to check out its efficiency, functional properties, and concerned problems before creating plenty of mock-ups or full mass production.

CNC machines are not only a time-saver but also cost-effective. Moreover, in the prototype you can assess the product's color, light, feel, shadow, resistance to motion, temperature to touch and quality, etc.

For Rapid Prototyping there are multiple different options in the market. These include sand casting, selective laser sintering, 3D printing, fabrication, and CNC Prototyping. While all have unique advantages, but our concern in this post is CNC Prototyping. Just follow up and we will comprehend its usage together.

Usage Of CNC Prototyping

Rapid Prototyping or CNC Prototyping has its roots in various industries including

or in all fields which demand finished products with great detail and precision. Let's explore the benefits of Using CNC Machining for Rapid Prototyping.

CNC Machining Provides Fast Services

Although the use of CNC Machining was started in the 19th century, yet its latest technology has changed its functional levels a lot.

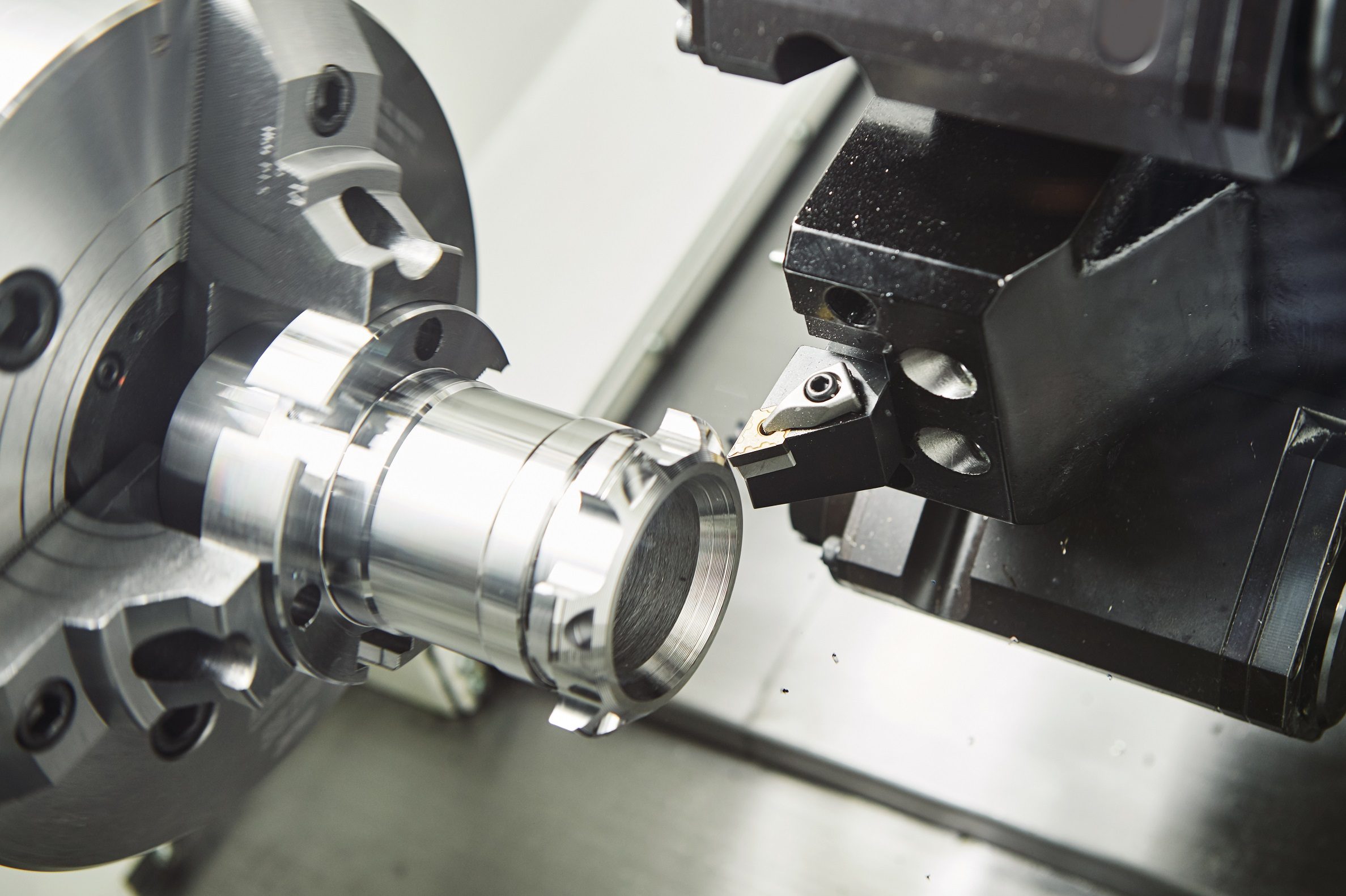

As a machine and software application, it has become more reliable and fastest to produce complex shapes not only in metal but also in plastic.

Firstly in modern CAD/CAM software, the three-dimensional part has the ability to translate into a G-Code cutting program and then convert it into a multi-axis mill within seconds.

Once the program is set, the raw shape of metal will convert into a finished part in minutes.

CNC Machining Takes No Fix Tooling

Although there are some manufacturing processes like plastic injection molding that takes rigid dies yet this does not happen in CNC Machining.

The tool used for cutting in CNC Machining is hardened metal cutting inserts which are put in the spindles. And these cutting inserts are replaceable attachments.

These cutting inserts have different shapes and sizes. Therefore these cutting inserts function differently.

But when you arrange these cutting inserts properly they can exchange and swap out in no time.

CNC Machining Provides High Accuracy

CNC Machining comes with 0.0001 higher accuracy and can work around the clock because it contains computer-cutting tools as compared to traditional machines.

You cannot rule out human error from conventional machines but you can stamp out mistakes from CNC machines because of its digital and autonomous template.

It produces a tolerance of 50 microns which is obviously enough in commercial applications.

And most interestingly this tolerance is repeatable.

A tighter tolerance ranging from ±0.0002 (±0.00508 mm) to ±0.0005 is required in heavy cuttings like aerospace, automotive or scientific tools under controlled conditions.

CNC Machining Has Flexible And Modifiable Properties

As it is based on a computerized program, you can alter any specification regarding color or design by changing a few lines of the actual G-Code program.

Its widely recognized advantage is to test different iterations immediately prior to the final touch to check out the result.

Due to customizable properties, CNC machines are highly recommended in Rapid Prototyping. Just change a few lines in digital files and get your required prototype!

CNC Machine Is Adjustable With Many Materials

CNC Machine is compatible with different materials be they hard plastic or rigid material (cannot melt or deform). It can digest any material like wood, foam, plastic, brass, copper, aluminum, polypropylene, fiberglass, titanium, etc.

For example, if you want to check out whether the product is durable in certain conditions you can order an aluminum prototype. If you want to test the tolerance of the product you can order a titanium prototype as the aluminum will not work in high temperature because it melts in heat.

This also helps in product development or in the preparation of similar prototypes with different mechanical properties.

Provide Product Uniformity With Prototype

The output which CNC machines provide is exactly the same as you imagined in your mind, be it one prototype or hundreds of thousands of prototypes!

And even conventional or traditional machines cannot produce the same result. That is the reason most manufacturers prefer CNC Machining for Rapid Prototyping.

Reusable Advantages

Reusability is another advantage of using CNC Machining for Rapid Prototyping. This benefit lets you allow to test multiple mock-ups of your prototype to understand which one will work better for your product. Cool!

Because once you feed the CNC machine regarding your desired prototypes, it will create several samples for your ease. Once you choose the best one you can reproduce hundreds of thousands of prototypes in the minimum possible time.

Note: not everyone can run the machine; only top-notch engineers or well-trained technicians can utilize these machines.

Conclusion

Rapid Prototyping is a superb option for those manufacturers who are looking to test products before getting the final version or mass production. Best choice for economical manufacturers!

As compared to 3D printing or injection molding, CNC Prototyping delivers quick results. CNC Prototyping allows you to test the quality of the materials in various ways, and if any amendment is needed you can do it by changing the code of the digital file.