Distribution Transformer Failure | What goes wrong?

Transformers plays a very important role in the power system. Though they are some of the most reliable component of the electrical grid they are also prone to failure due to many factors both internal or external. There could be many initiators which cause a transformer failure, but those which can potentially lead to catastrophic failure are the following :

- Mechanical Failure

- Dielectric Failure

In both cases, the transformer is no longer able to perform its intended function of carrying load and stepping down (or up) the voltage. The main point of concern in ageing and the life expectancy of transformers is the condition of the insulation system, which is typically based on organic products.The organic products in a transformer degrade over time and finally they lose the capability to withstand the stresses a transformer might see in daily life

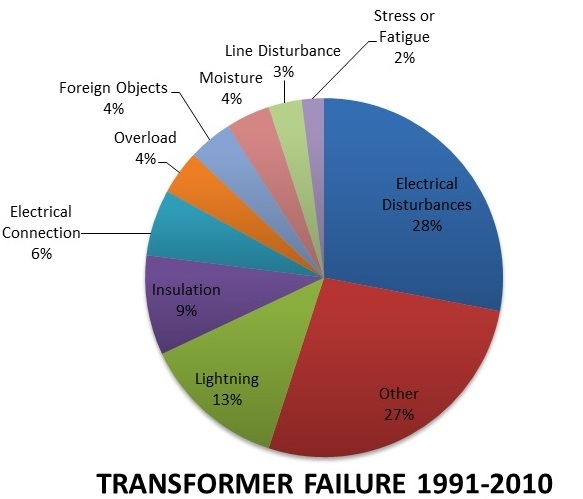

Some of the most common causes of transformer failure are :

- Lighting Surges

- Poor Workmanship-Manufacturer

- Overloading

- Inadequate Maintenance

- Line Surges/External Short Circuit

- Deterioration of Insulation

- Moisture

- Sabotage, Malicious Mischief

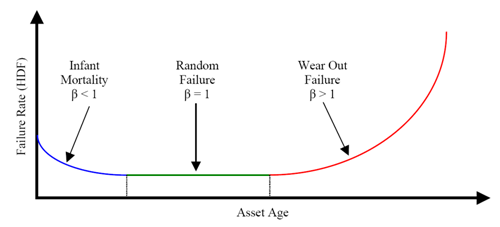

The Bathtub Curve

The following graph describes the relative failure rate of a whole group of similar products like transformers. During their life cycle, transformers will go through three different periods of failure rates, which explains the “bathtub” shape.

Let's explain:

- Infant Mortality : Failures are the least expected. Design, manufacturing or material defects are common causes and requires from the manufacturer a deep analysis of the incidents.

- Normal Life : Also called useful life where random failures may occur. This is the lowest constant failure.

- End of Life Wear-out : Wear and tear make products fail more often and signal the end of life.

types of transformer failures

Transformer Failure appear in different ways, depending on the type of construction. Some modes of failure can occur regardless of construction type. These might include tap changer failures, bushing failures, tank failures, moisture ingress, and other forms of dielectric fluid contamination. Sometimes the failure could be purely due to lack of regular maintenance or lack of awareness. And sometimes it could be due to natural causes like lightning which causes electrical surge in the power lines. In more interesting fashion it sometime also happens due to snakes, squirrels etc.

According to a latest 'Technical Paper' and transformer failure report published by OMICRON, up to 26% of the major transformer failure is related to tap changer.

Up to 26% of major transformer failures are related to the tap changer !

An example of a detailed transformer failure report of a 315MVA which failed at Bamnauli Substation, Delhi-India can be found here.

Mechanical Failure

Mechanical failures can be the result of shipping damage, seismic activity, and thru-faults. The obvious result of a mechanical failure is the displacement of winding turns or damage of the turns by the forces exerted during the damaging event. Mechanical failure can result in scalloped conductors (beam failure), conductors which have been looped over adjacent turns by the hoop stress (hoop failure), or in rare cases, conductors which have been severed by the tension applied by the hoop force. That’s why it’s highly recommended to perform a SFRA (Sweep Frequency Response Test) test on site to observe any change in the SFRA test result in comparison to the factory results. Doble's M5400 Sweep Frequency Response Analyzer well renowned for carry out the SFRA tests.

Indications for Mechanical Failure

Moreover change in low voltage excitation current, a change in impedance, and sometimes, the presence of partial discharge (PD) during an induce voltage test can also give valuable indications about a mechanical failure in the transformer. Mechanical failure is often discovered by electrical failures which are the result of mechanical deformation.

Electrical Failure

Electrical failures are the result of insulation degradation. This can be caused by thermal degradation over the life of the transformer, by thermal degradation due to excessive or frequent fault current, or by dielectric breakdown due to high voltage stress. A dielectric breakdown can also be the result of mechanical forces tearing the insulation. The result of a electrical failure can be a turn to turn failure. The consequences can be arc from the energized winding to an adjacent winding or to ground. It is important to note that overloads rarely result in transformer failures, but do cause thermal aging of winding insulation.

According to a detailed article at Electrical Engineering Portal, when a transformer becomes hot, the insulation on the windings slowly breaks down and becomes brittle over time. The rate of thermal breakdown approximately doubles for every 10°C. 10°C is referred to as the “Montsinger Factor” and is a rule of thumb describing the Arrhenius theory of electrolytic dissociation. Because of this exponential relationship, transformer overloads can result in rapid transformer aging. When thermal aging has caused insulation to become sufficiently brittle, the next fault current that passes through the transformer will mechanically shake the windings, a crack will form in the insulation, and an internal transformer fault will result.

Based on construction of transformers

Transformer Failure modes for shell form construction

Shell form construction is resistant to winding deformation due to thru-faults.This is because the coil “pancakes” are arranged in multiple groups to limit force magnitude. The exposure to conductor bending is limited by many support spacers to avoid beam bending. Form fit tank and core prevent movement of the core and winding groups.

The area which is vulnerable is the edge of the coil where “pancake” windings are connected together. There is a relatively high voltage in the kV range at this point between the same end of odd or even number “pancakes”. Failure can be prevented by adequate support of the outer turns.

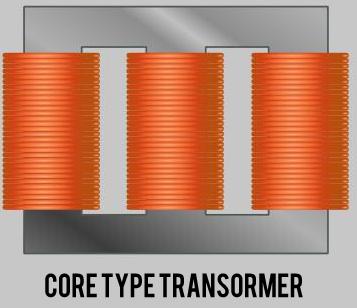

Winding failure modes for core form construction

Core form construction can exhibit failure in several ways. Radial tension failure, also known as hoop tension failure, can occur;conversely, radial compression failure can also occur. Radial failure can collapse the inner winding unless the winding support structure is strong.

Axial failures can occur in both compression and tension. Sometimes the windings telescope, caused by uneven axial forces.The result is typically a tangled mess of winding conductors which eventually arc to ground or each other, and disrupt the force vectors in ways that were not accounted for in the original design.

Core form designs have subsets consisting of numerous winding configurations such as layer windings, helical (or spiral-type)windings, continuous disc, and interleaved disc windings. Each has different voltage stress applied to different components of the winding (individual strand to-strand, conductor-to-conductor, layer to-layer or disc-to-disc, etc.)

Indications for Electrical Failure

Electrical failures will manifest themselves as a source of dissolved gas products. Diagnostic tests will typically show deterioration and the results will provide clues where the failure occurred or where it is about to happen. Winding turns ratio, winding insulation tests, insulation power factor will all give indications and should confirm the DGA results. They frequently show results observed during an internal inspection or tear-down as some form of insulation “burning” which appears as discoloration or carbonisation of cellulose. Those where cellulose is not involved typically show as points of contact on core steel or tank steel and winding or leads where the conductor is bare.

Common Distribution Transformer Failure Analysis

Other causes of distribution transformer failure modes can be the result of a grounded core or core clamping structures (such as through-bolts) that develop shorts. These result in a shorted turn (the core) and produce high currents which are often detected by dissolved gas analysis. Transformer can also fail due to poor maintenance. Especially when there are leakages in the transformer tank and the transformer oil level drops below a certain level which gives rise to local heating in the windings which will eventually fail if there is no transformer oil to cool down the temperature. Thus it's very essential to carryout regular oil filtration of the transformer and leak arrests before it becomes very critical. Preventive maintenance is the key to avoid such kinds of disasters.

Now let's try to another three important factors which could also lead to the failure of the distribution transformers :

Craftsmanship

Probably one of the most important factor in transformer life is the level of the craftsmanship, the quality of manufacturing process and controls placed to keep a check on the process. Which unfortunately is overlooked where we try to automate all our manufacturing process.

Material

After craftsmanship comes the most important factor : material. According to experts using the right wire and insulating materials makes an enormous difference in the life of the transformer.

It's also important to use the right iron core material. It should be original and not recycled. According to studies the best material to use for the core is magnetic silicon steel with thinner thickness.

Design

Design also plays an important role in the life of a transformer. Round-wound transformer designs are preferred as it reduces the voltage stresses, stay cooler, don't create noise and also offers less risk of short circuit with sheet wound secondary.

Here is a short video the showing the devastating consequences when an electrical transformer explodes :

Other Miscellaneous Transformer Failure

Loose connections : Due to long term vibration, connections can loosen in the transformer. If this goes unnoticed it might lead to excessive buzzing and overheating.

Excessive Harmonics : If a higher temperature is observed at the neutral termination then it's an indication of the presence of harmonics. Usually the harmonics on the third and fifth level indicates interference from the electronics loads.

Unbalance Loads : Due to the presence of the unbalance load in the power system a higher temperature on the one of the phase may occur resulting in local heating.

Cooling issue : Some times the cooling fans are out of order or the transformer is suffering a severe oi leakage resulting in the increase of temperature inside.

Solution : Preventative Maintenance of Transformers

Since the operational situations of a transformer keeps changing over its life time so does its expected life time. An important point to be noted is that the transformer should not be loaded more than 80% of its capacity otherwise it’s life deteriorates quickly overt time. Therefore, a proper maintenance program should be in place in order to for the aging process to be quantified and tracked so that catastrophic failures can be avoided.

Having a good transformer maintenance program in place will result in the following benefits:

Why Preventive Maintenance for Transformers?

A good transformer maintenance program should have regular electrical testing of the transformer for different parameters like turns ratio, excitation current, polarization index, insulation resistance, short circuit impedance etc.

But since it’s not possible for all the tests to be carried out on transformer on a regular basis a predictive maintenance program for transformer is essential since it provides trending data to help anticipate and plan future maintenance activities, which saves time and money.

Keeping the above point in mind below are some of the few important and very essential test which should be carried out and can give us an overall picture of the health of the transformer:

With the above tests in place a transformer is being tested for 4 major parameters: electrical, geometrical, magnetic and dielectric. Thus by having a good and reliable transformer maintenance program catastrophic failures and high cost repairs can be avoided.

In addition to the above test oil sample should be taken a series of test should be conducted on a regular basis in order to determine the dielectric strength of the insulating oil inside the transformer. In case of a lower dielectric value transformer filtration should be carried out for the transformer by taking it offline. After the oil filtration is carried out a sample of the oil should be taken and Break Down Voltage (BDV) should be carried out to check the dielectric strength of the oil.